The Largest Online Inventory of

Ford Tractor Starter

New to This Site? Look at this Video Tutorial

on How to Select Tractor Starters

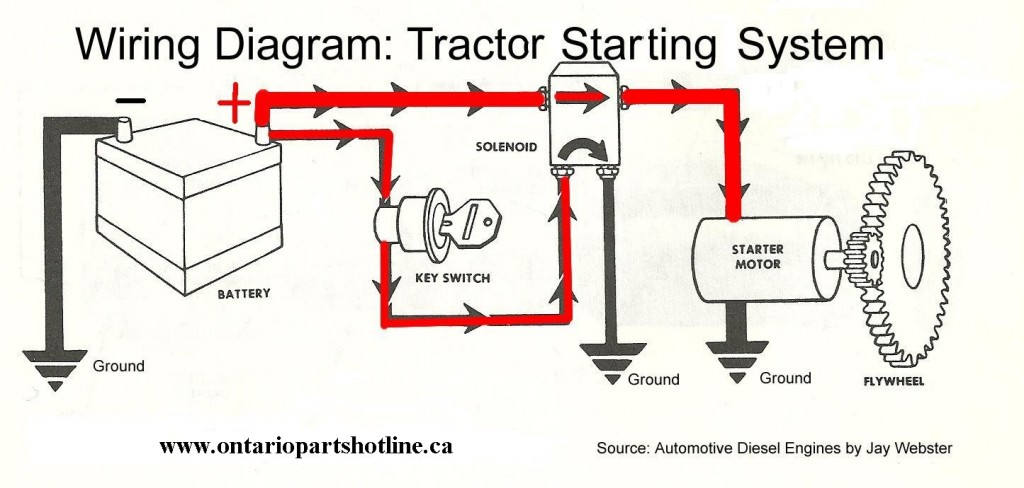

The Ford 4000 Tractor was manufactured in a multiple variety of fuels, engine models and transmission types.  The engine, for example, can be either diesel fuel, or LP gas. The diesel engine comes as the four (4) cylinder 172CD Diesel engine, or as the three (3) cylinders CID Diesel engine. The diesel engines were a latter addition to the Ford line of tractors, with the earlier models initially manufactured for gas. The gas engines were the four (4) cylinder 172 CID Gas engine, the three (3) cylinders 192 CID Gas engine, and the three (3) cylinder 201 CID gas engine.The starter for the diesel engines are typically larger and more powerful than the smaller gasoline engines, as diesel engines compressions needs to be overcome to initiate the starting process.The starter for the diesel 4000 engines is the 83981923. This is a 10 teeth clockwise (CW) rotation, Lucas Ford Tractor Starter that operates off of 12 volts (V). This one starter can be used on a multitude of machines, including the Ford backhoe 400 series and the 500 series, swather, TW series, 2000, 3000, 4000, 5000, 6000, 7000, 8000 and the 9000 series tractors. This Ford Tractor starter weights in at approximately 29 lbs.In Comparison, for gas engines is the D7NN11001A. This weighs 17.26 lbs, has nine (9) teeth, clockwise (CW) rotation, and operates off of 12 volts (V), and is used on several of the wheel loaders, and a multitude of tractors. The part number C3NF11002CR is identical in specifications to the D7NN11001A, and is used on similar gas tractors.The third type of Ford Tractor Starter is the C3NF11002DR, which is used with six (6) volts (V) systems. The specifications are 9 teeth starter drive and clockwise rotation (CW). This is the early starters that were manufactured with the starter solenoid as a separate part. The ford tractor solenoid for this starter is part number D8NN11350CA, and is sold as a separate component.This six(6) volts (V) gas tractor is mainly used on the 500, 600, 700, 800, and 900 series tractors. The engine, for example, can be either diesel fuel, or LP gas. The diesel engine comes as the four (4) cylinder 172CD Diesel engine, or as the three (3) cylinders CID Diesel engine. The diesel engines were a latter addition to the Ford line of tractors, with the earlier models initially manufactured for gas. The gas engines were the four (4) cylinder 172 CID Gas engine, the three (3) cylinders 192 CID Gas engine, and the three (3) cylinder 201 CID gas engine.The starter for the diesel engines are typically larger and more powerful than the smaller gasoline engines, as diesel engines compressions needs to be overcome to initiate the starting process.The starter for the diesel 4000 engines is the 83981923. This is a 10 teeth clockwise (CW) rotation, Lucas Ford Tractor Starter that operates off of 12 volts (V). This one starter can be used on a multitude of machines, including the Ford backhoe 400 series and the 500 series, swather, TW series, 2000, 3000, 4000, 5000, 6000, 7000, 8000 and the 9000 series tractors. This Ford Tractor starter weights in at approximately 29 lbs.In Comparison, for gas engines is the D7NN11001A. This weighs 17.26 lbs, has nine (9) teeth, clockwise (CW) rotation, and operates off of 12 volts (V), and is used on several of the wheel loaders, and a multitude of tractors. The part number C3NF11002CR is identical in specifications to the D7NN11001A, and is used on similar gas tractors.The third type of Ford Tractor Starter is the C3NF11002DR, which is used with six (6) volts (V) systems. The specifications are 9 teeth starter drive and clockwise rotation (CW). This is the early starters that were manufactured with the starter solenoid as a separate part. The ford tractor solenoid for this starter is part number D8NN11350CA, and is sold as a separate component.This six(6) volts (V) gas tractor is mainly used on the 500, 600, 700, 800, and 900 series tractors.

Most of these starters are manufactured by Lucas, and there are two different starter solenoids that are available, namely the part numbers D7NN11390B, and the E4NN11390AC, with the latter being used on diesel engines only, and the former that can be used on a combination of gas or diesel engines. Replacement starter drives units are sold separately, for either the 9 teeth or the 10 teeth ford starter drives. |